The term Industria 4.0 derives from the so-called ”4th Industrial Revolution“. The world economy is indeed experiencing an epochal transformation. Let’s briefly go through the stages involved:

1st Industrial Revolution (late 1700):

Introduction of steam power for operations at manufacturing plants

→ use of machines powered by mechanical energy

3rd Industrial Revolution (1970):

Use of electronics and IT to further automate production

→ Industrial robotics

2nd Industrial Revolution (early 1900):

Introduction of electricity, chemicals and oil

→ Mass production and assembly lines

4th Industrial Revolution (today):

Use of intelligent machines connected to the internet

→ Connections between physical and digital systems, complex analysis via Big Data and real-time adaptations

The 4th Industrial Revolution

The fourth industrial revolution has mainly taken place due to the availability of “intelligent machines”, computational technologies, big data, new materials and components that are entirely computerised and linked (the system that is defined as the internet of things and machines).

The new industrial manufacturing processes are based on robotics and mechano-tronics, but also – increasingly – on the use of advanced ICT technologies for automating the manufacturing and processing phases.

Industria 4.0 requires innovative technological solutions that are increasingly efficient. It also aims to encourage collaborations between businesses through methods of distributed planning, the integrated management of network logistics and inter-operability of computer systems.

Industria 4.0: Anticipated benefits

- Greater flexibility through the production of small batches at large scale batch costs

- Greater speed from prototype to mass production through the use of innovative technologies

- Increased productivity through lower set-up times, error rates and equipment downtime

- Better quality and less waste by using sensors that monitor manufacturing processes in real time

- Greater competitiveness of products thanks to greater functionality deriving from the Internet of Things

The 4.0 Industria Plan in Italy

The Budget Act 2017 implemented the National Business Plan 4.0 which has brought industrial policy back to the centre of the Government’s agenda. The Industria 4.0 Plan was introduced by Carlo Calenda, the Minister for Economic Development, and is often referred to as the “Calenda Plan”.

The package contains numerous tools for relaunching the competitiveness of Italian businesses, and supporting them with their investment and innovations programs. How? By introducing or strengthening tax incentives and investing in research and development.

The greatest ambition is to disseminate a new business culture focused on the skills needed to maximize the benefits of the new technologies that drive Industria 4.0.

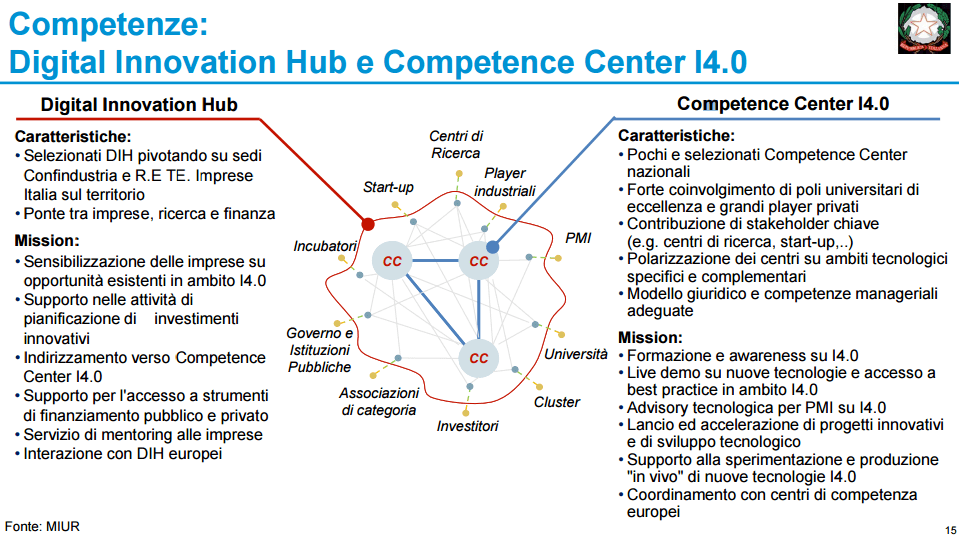

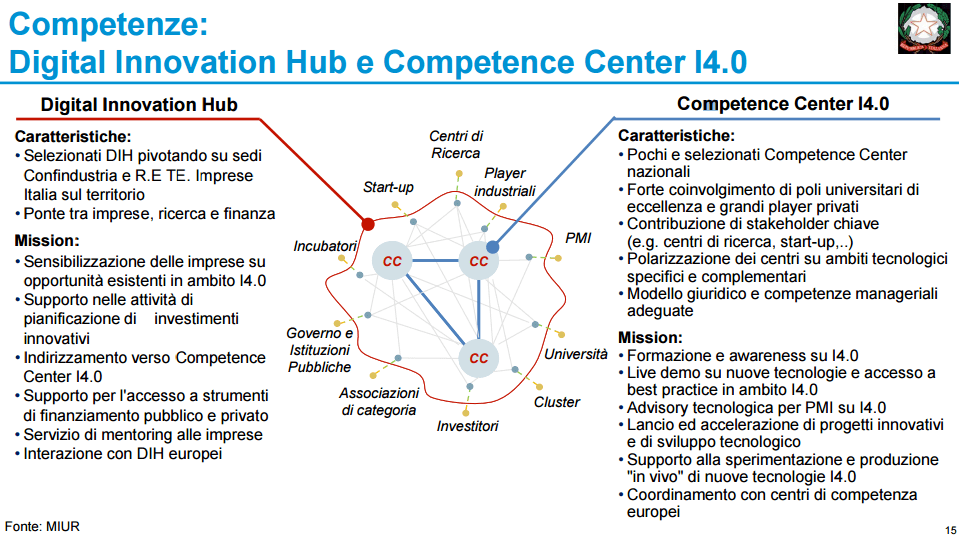

Setting up the Digital Innovation Hub and Skills Centre

To respond to the needs of businesses, the Government has defined the Industria 4.0 national network: a network distributed across the territory with the aim of advising and supporting businesses with digital transformation, and putting the culture of Industria 4.0 into practice.

The plan set up two new entities: the Digital Innovation Hub (DIH), innovation hubs present throughout Italy – with connections to Confindustria, Confartigianato, Confcommercio and CNA – and Skills Centre (CC) which makes reference to several Italian universities.

DIH on the ground

Digital Innovation Hubs forms a bridge between businesses, research and finance.

These have provincial, regional or inter-regional dimensions to maximise the proximity of businesses, and have to have a sufficient critical mass (demand) of businesses to serve.

At a logistical level, they are centred on regional Confindustria companies with enough territorial “articulations” (territorial associations) to perform a capillary action that’s focused on the needs and characteristics of SMEs.

The Digital Innovation Hub of Belluno Dolomiti was one of the first to be established in Italy.